Pressure tanks are used in a variety of applications, most commonly as an effective way to improve system efficiency. Pressure tanks are so efficient and cost-effective becaue they because they keep pumps from running constantly. In doing so, the pressure-regulating tank increases the longevity of the pump and motor and also reduces maintenance and down time. Let's dive into a step-by-step on how to size a pressure tank.

Contents

What You Need to Know Before Starting

Basic Sizing Guidelines for your Pressure Tank

What You Need to Know Before Starting

In order to properly size your pressure tank, there are a few key data points you should find out:

- Flow Rate

- Cut-in/Cut-out Pressure

- Target Run Time

Most manufacturers suggest a run time of less than one minute if the motor is under 1 horsepower. If the motor is over 1 horsepower, then a run time of 2 minutes or more is common. Always confirm this with your tank manufacturer of choice as guidelines can vary.

Basic Sizing Guidelines for your Pressure Tank

As a rule of thumb, one can follow these guidelines when sizing a pressure tank:

- 0-10 GPM: 1 gallon of drawdown per 1 GPM of flow

- 10-20 GPM: 1.5 gallons of drawdown per 1 GPM of flow

- 20 GPM+: 2 gallons of drawdown per 1 GPM of flow

Drawdown can be defined as the amount of volume loss in the tank as the plumbing system "draws" off this pent up pressure. After all, the purpose of a pressure tank is to maintain pressure in a given system and give the pump a break. This way, the pump doesn't need to run constantly to remain at system pressure. While a pressure tank can appear costly up front, it will save in the long run - less run time for the pump means less maintenance and less money in energy costs.

Pressure tanks come in several orientations - the most common being vertical, horizontal, and inline. Be sure to choose the orientation that best fits your plumbing configuration and available space.

Once we have identified our flow rate in gallons per minute (GPM), have identified our cut-in/cut-out pressure, and confirmed our target run time - we must determine what cut-in/cut-out pressure we want to set the system at.

Pressure Tank Sizing Explained

One key equation to remember when sizing a pressure tank is:

Flow Rate X Run Time = Tank Draw Down Capacity

For example, let's say we have a pump that produces 5 GPM and is powered by a 3/4 HP motor. Since the motor that is less than 1 HP, we'll assume that our tank manufacturer recommends a 1-minute runtime. We want to design this system to cut-in (turn on) at 40psi and cut-out (turn off) at 60psi.

5 GPM X 1 Minute = 5 Gallons of Draw Down (at 40/60PSI)

So, we will need to select a tank that allows for 5 gallons of draw down at a pressure setting of 40PSI cut-in and 60PSI cut-out. A typical vertical tank that fits our needs would be a WOMAX-220. If our plumbing layout would accommodate a horizontal tank better, we could select a WOMAXH-220. This would give us approximately 3.5 minutes of run time before the pump would cycle back on.

Horizontal pressure tanks also have a plastic pump stand so you can maximize space when designing a plumbing system - certainly a nice feature in confined plumbing configurations where space is at a premium.

Relationship Between Pressure & Tank Size

Another important consideration is that as operating pressure increases, the usable drawdown decreases - meaning you’ll need a larger tank to compensate. Pressure and tank size are directly related: higher pressure settings reduce drawdown, which increases the tank size required to achieve your target run time.

After we have these three points determined, we can then proceed with sizing our pressure tank. Pressure settings are another important factor with any plumbing system. The most common pressure settings are 30/50, 40/60, and 50/70. Most manufacturers will have a pressure tank sizing chart that will allow viewers to quickly size a tank's drawdown based upon their system's pressure settings.

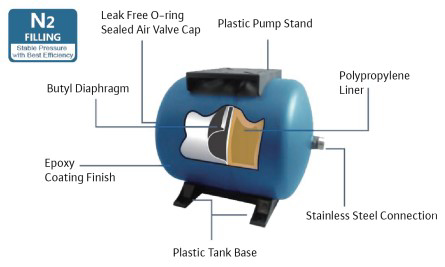

If you’d like to explore specifics, we can provide detailed sizing information for the Wilo MaxAir® product line. Just give us a ring during our business hours or visit www.dultmeier.com any time. Below is a cutaway view of a Wilo MaxAir® horizontal tank, highlighting key features that set it apart from the competition and make it one of the top options in the market today.

Cutaway of Wilo MaxAir Horizontal Pressure Tank

You can view the full offering of Wilo MaxAir® Pressure Tanks right here on dultmeier.com. Have questions about pressure tank sizing or another application? Don’t hesitate to reach out! That’s what we’re here for.

Your Experts in Delivering Fluid Handling Solutions - We Know Flow!