The term 'transfer pump' is commonly used to describe any type of pump that moves fluids from one location to another. Centrifugal pumps are often used as transfer pumps for large volumes, but different pump types can be used. It all depends on the application.

There are so many pump types used across various industries that selecting the proper pump for your task may seem overwhelming, but we can help narrow it down! We have decades of combined experience finding pumps to fit specific applications. From high-volume water transfer to pumps to small pumps that deliver fluid in low doses, and everything in between.

Let's run down the types of transfer pumps, then walk through how to select the proper pump for your needs.

What is a Transfer Pump?

All pumps move fluid, but typically, we think of a transfer pump as a low-pressure means of moving fluid from point A to point B in an efficient manner. This differs from pumps intended for specific applications, such as piston or plunger pumps, which are designed to generate high pressure to facilitate some task or process, such as cleaning or dosing.

Transfer pumps need to be compatible with whatever fluids you need to move, and they should be sized for maximum efficiency based on the requirements of the task and budget.

Different Types of Transfer Pumps

Here are the basic pump types used for transferring fluids:

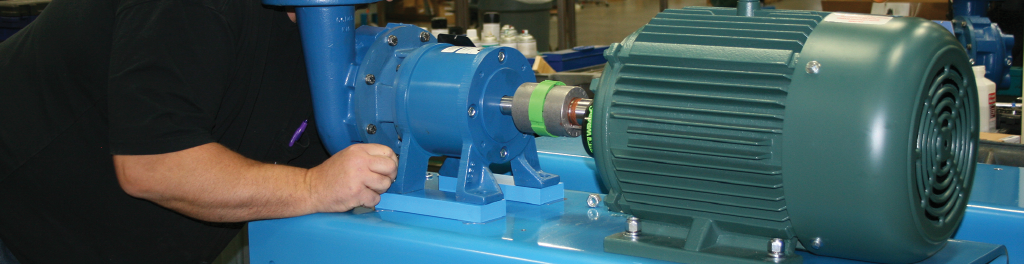

Centrifugal Pumps

Most people probably think of a centrifugal pump when using the term transfer pump. They are made for moving high volumes. Centrifugal pumps stand apart from other pump types because they work on different principles. Centrifugal pumps move low-viscosity fluids using a spinning impeller, producing a smooth flow that changes with pressure.

The majority of other pumps fall into the positive displacement pump category (roller pumps, gear pumps, diaphragm pumps, etc). These pumps move fluid by trapping and pushing fixed amounts, making them ideal for thicker liquids and steady flow needs.

Why does this matter? A centrifugal pump performs differently from positive displacement types. A centrifugal pump is only as effective as its plumbing. More detailed explanations of the types of pumps and how to maximize flow rate with plumbing can be found in this guide.

Common Uses: Water, wastewater, light oils, diesel, brine, fertilizer, chemicals

How They Work: Use an impeller to create centrifugal force that moves fluid by adding "head"

Examples: Self-priming pumps, multistage pumps, submersible pumps, trash pumps

Bottom line: Use a centrifugal pump to move large volumes of water or other low-viscosity fluids. If you're not sure what pump you need and flow is more important than pressure, start with these pumps.

Positive Displacement Pumps

While centrifugal pumps rely on velocity and kinetic energy to move fluid—and are ideal for high-flow, low-pressure applications—they aren’t always the best choice when consistent flow is required under varying pressure. That’s where positive displacement pumps come in. Unlike centrifugal models, these pumps move a fixed volume of fluid per cycle, delivering a steady, predictable flow regardless of changes in system pressure (within design limits).

Gear Pumps

When a fluid is too thick or viscous for a centrifugal pump to work efficiently, a gear pump is often a great option. Gear pumps consist of a housing enclosed around two gears, driven by a single drive shaft. They are simple, compact pumps that can be installed easily.

Unlike centrifugal pumps, they will push liquid through restrictions and maintain flow up to a certain pressure limit. Gear pumps can also be equipped with internal relief valves to protect the pump & plumbing from damage if the pump becomes deadheaded or significantly restricted.

They work especially well with high-viscosity, non-abrasive fluids and are commonly used in systems requiring consistent volume and pressure.

Common Uses: Heavy oils, liquid feeds, hydraulic fluids, chemical transfer

How They Work: Rotating gears trap and move fluid through the pump chamber

Examples: Cast iron gear pumps, stainless steel chemical gear pumps, hydraulic-drive gear pumps

Bottom line: Choose a gear pump for clean, viscous fluids where steady flow and moderate pressure are needed. They’re durable, compact, and easy to maintain.

Diaphragm Pumps

Diaphragm pumps are often the preferred choice for viscous fluids over gear or centrifugal pumps due to their unique pumping mechanism and fluid-handling capabilities.

Unlike centrifugal pumps, which lose efficiency as viscosity increases, diaphragm pumps use a flexing diaphragm to physically push fluid, making them ideal for thick, sticky substances that don’t flow easily. Performance remains strong even with very high viscosities.

Compared to gear pumps, many diaphragm pumps (specifically AODDs or air-operated double diaphragm pumps) offer better solids-handling and are more tolerant of abrasive or shear-sensitive fluids. They can run dry without damage, are typically self-priming, and provide gentle, pulsed flow that won’t damage the product—especially important for slurries, food products, coatings, or chemicals.

Common Uses: Corrosive chemicals, wastewater, fuel, food products, thick slurries

How They Work: A flexible diaphragm moves back and forth to create suction and discharge

Examples: High-pressure diaphragm pumps, air-operated double diaphragm pumps (AODDs), chemical dosing pumps

Bottom line: Diaphragm pumps are best for thick, abrasive, or sensitive fluids—especially when chemical resistance, dry-run capability, or portability is important.

Vane Pumps

There are different types of vane pumps, but they are known for their ability to handle vapors. They are often the best choice for handling fuels compared to centrifugal and other pump types. They also provide precise, consistent flow regardless of pressure, a key advantage over centrifugal pumps, whose flow drops significantly as system pressure increases.

Compared to other positive displacement pumps like gear or piston types, vane pumps are smoother and more forgiving with thin, volatile fluids. They handle small amounts of vapor or air without stalling, and their sliding vanes maintain tight internal sealing, ensuring efficiency with even the lightest fuels.

Common Uses: Gasoline, diesel, jet fuel, kerosene, light oil

How They Work: A rotor with sliding vanes spins inside an eccentric chamber, trapping and moving fluid toward the discharge

Examples: Rotary vane fuel pumps, mobile fuel transfer pumps such as Fill-Rite FR700 or 1200 series

Bottom line: Use vane pumps when transferring fuel or other thin liquids that require consistent delivery and strong suction, especially in mobile or metered systems.

Key Factors to Consider When Choosing a Transfer Pump

Each of these pump types is suited to specific applications and fluid types, with various sizes and configurations available within each type. The selection of the right transfer pump depends on factors such as fluid viscosity, chemical compatibility, pressure, flow rate requirements, and environmental conditions.

We can begin to zero in on the right pump type or family of pumps by considering several questions:

What are you transferring?

Is the fluid clean or does it contain solids (e.g., sand, sludge, slurry)?

Is the fluid thick or viscous (e.g., thick oils, molasses) or thin (e.g., water, gasoline)?

Is the fluid corrosive or chemically reactive (e.g., acids, solvents, fertilizers)?

Is the fluid flammable or hazardous (e.g., gasoline, diesel)?

With any liquid, it is important to consider the best pump materials. There is no "one-size-fits-all" material, and sometimes the best option for even a corrosive or acidic substance is not always the most expensive. We reference chemical compatibility charts put together from industry research to identify what works.

With several different types of fluids, such as diesel, DEF, and fertilizer, we can make recommendations and identify pumps based on experience and direct feedback from users. Once we know the liquid, we can discuss the flow requirements and your system's plumbing.

How much flow do you need?

This is important, but it can be hard to gauge. You may not know the exact gallons per minute flow, but we can look at the amount of time you want your task accomplished. If the goal is to fill semi-tankers that range from 3000-5000 gallons in capacity and you want to do it in 8 minutes or less, you will need a pump that can move over 600 GPM through your plumbing.

If you need to fill five-gallon buckets from a tote or storage tank, you need to consider how long you want to stand there filling. A 10 GPM pump might do it in 30 seconds, but it could be way more costly than a 5 GPM pump. Maybe filling twice as fast will justify the cost, and maybe not; this, of course, depends on your situation.

How far and how high are you pumping?

Flow rate may be the key, but there is more to it than just the pump; it’s important to consider your hose/pipe diameter, plumbing layout, and other items like strainers, flow meters that add backpressure. They all affect actual performance, especially for centrifugal pumps. A pump may be capable of high flow, but undersized hoses, restrictive fittings, and sharp bends can really limit flow rate for centrifugal pumps and build excessive system pressure for positive displacement pumps.

Elevation changes and long discharge lines also create backpressure, reducing efficiency. To select the right pump, factor in not just the fluid and flow rate, but the entire system—plumbing, elevation, and restrictions included.

At Dultmeier, we use software and have staff well-versed in sizing pumps according to your existing or planned plumbing. If you can provide details, we can guide you to a pump that will work and stand behind it through the entire process to ensure proper performance, even if that means helping you identify adjustments in your layout to achieve greater efficiency.

Total Dynamic Head

The details of your plumbing will allow us to determine the total dynamic head or TDH. With this information, we can identify the flow rate a pump can produce within your system. We use the pump curves provided by the manufacturers to find this information. You can learn more about pump curves in our centrifugal pump sizing guide.

Additional Transfer Pump Details to Consider

Once the liquid is known and flow requirements are determined based on the plumbing system, we can examine some more specific questions:

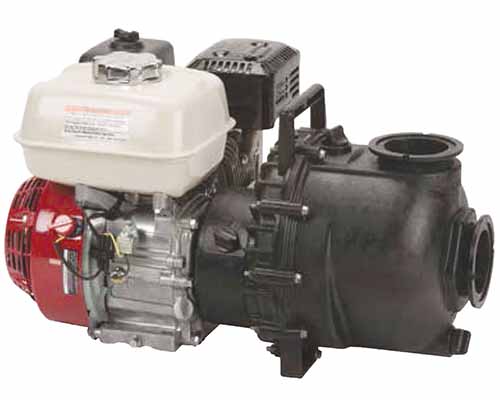

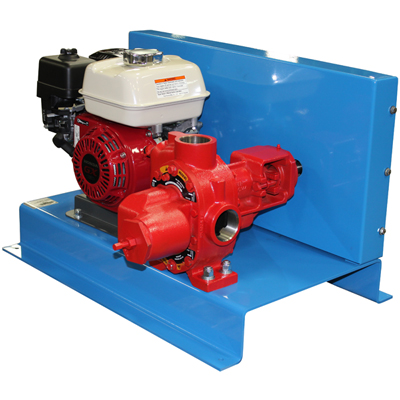

What type of power source is available?

- Electric (110V, 220V, 1-phase or 3-phase?)

- Gas engine

- PTO

- Hydraulic

- Air (compressed air)

How often will this pump run? Occasional use, daily, continuous 24/7; this will help determine the proper motor or drive type.

Will the pump be mobile or stationary?

Is the pump above the fluid source, or will it be flooded/suction-fed? Not all pumps are self-priming and need to be gravity-fed.

Do you need it to run dry? Some pumps, like AODDs or "wet seal" centrifugal pumps, can run dry safely; others can’t.

Transfer Pump Selection FAQ

What is the best pump for DEF?

Many different pump types can handle DEF. The key is finding a pump made from compatible materials. You can see the exact pumps suited for DEF in this guide.

What is the highest flow transfer pump?

Centrifugal pumps are designed for high-volume transfer; however, there are other factors to consider. Fluid type and plumbing plays a major role. Be sure to read our guide on the highest flow pump options for different fluid types.

Can a transfer pump run dry?

Not all pumps can run dry safely. Air-operated diaphragm pumps (AODDs) and some "wet seal" centrifugal pumps are designed for dry-run tolerance. However, most centrifugal, gear, and vane pumps require fluid for lubrication and cooling—running them dry can damage internal components. Always check the pump’s dry-run capability before operating.

How far can a transfer pump push water?

The distance depends on the pump’s flow versus head curve and the plumbing system's total dynamic head (TDH). Most centrifugal pumps can push water hundreds of feet horizontally if the elevation change is minimal. For vertical lift, check the pump’s maximum head—this represents the highest net elevation gain (net vertical head) it can push fluid.

Need Help?

If you need help pinpointing a pump that will work for you, contact us and speak to one of our experienced staff members.

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.

Article reviewed by Tom Hansen, P.E.