Pump “size” can mean a lot of different things: Flow rate, port size, horse power required, or just how much space does the sucker take up! So when you are looking for a sprayer pump, you must consider several factors. But don’t worry, it is not complicated, and this article will provide the answers you need.

Key Takeaways (TL;DR): Sizing a Sprayer PumpDon’t just guess when picking a sprayer pump. Start by figuring out your flow rate (nozzles × GPM), then add 25–30% to handle things like pressure loss, agitation, and future upgrades. Make sure your pump can handle the pressure too—tree spraying needs way more PSI than a spot sprayer. Whether you’re running a boom sprayer, de-icer, or handgun rig, matching the pump to your setup means better performance, less wear, and fewer surprises in the field. |

Identify Your Sprayer Type

First, you need to understand the needs of the specific type of sprayer you’re using—whether it's for tree spraying, agriculture, de-icing, or anything else—this is the first step. Sprayer type will inform you of the pump type you will need, as well as both the pressure and flow rate that is required. After all, not all sprayers will require the same fluid and pressure output.

Typical Flow & PSI Requirements for Different Sprayer Pump Types:

Sprayer Type | Flow Range (GPM) | Pressure Range (PSI) |

Boom Sprayer | 1-100 | 15-120 |

Boomless Sprayers | 3-100 | 20-60 |

Spot Sprayers | 1-5 | 15-60 |

Tree Sprayers | 10-50 | 150-700 |

De-Ice Sprayer | 50-200 | 15-60 |

These amounts are general ranges for common sprayers and can vary. For a detailed breakdown, you can refer to our guide on the different types of sprayer pumps.

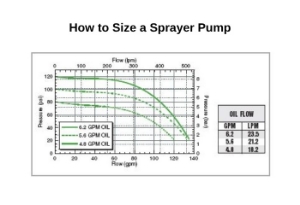

Calculate the Required Flow Rate

Once you know what type of pump you will need for your sprayer, you can then determine the size of the pump in regard to flow rate. To determine the required flow rate, you need to know some pieces of information. These pieces of information will vary slightly, depending on the type of sprayer, which again is why you start by determining what sprayer type you have.

Calculating Flow Rate for a Boom Sprayer

Flow requirements for your sprayer boom depend upon both the number of nozzles on the boom and the size of the nozzles. Once you identify the size of each nozzle or the flow rate per minute of each nozzle, you need to take that flow rate and multiply it by the total number of spray nozzles.

Boom sprayer nozzles typically follow a color code. This will tell you the nozzle flow rate at various PSI. You will want to use the nozzle flow rate at the higher end of its operating pressure range. If you don’t yet have your nozzles sized or are uncertain what size nozzles you have, this guide will show you how to identify nozzle sizes. Then you can examine the nozzle chart for flow rates a various PSI.

If you have a “boomless” sprayer, the process is no different, although you may only have one or two nozzles. Likewise, a spot sprayer or spray rig with a single spray gun would only have one nozzle to account for.

Example Calculating Required Sprayer Boom Flow Rate:

Let's look at an example: if your sprayer boom has 18 nozzles that have a flow capacity of 0.4 GPM (gallons per minute), you will take 0.4 x 18. This gives us 7.2 gallons per minute. So we need a pump that is capable of delivering this flow rate; however, we are not done yet. We still need to examine some other factors.

Account for Pressure Increase

Multiplying the number of nozzles by their GPM capacity gets us started — but that alone often isn’t enough. Here's why we will need to consider more than just flow:

Extra Capacity for Increases in Travel Speed

If you speed up in the field but don’t change your nozzles, your sprayer must push more liquid through them to maintain the same application rate (gallons per acre). That means your system needs a higher flow rate — and your pump has to keep up. If the pump is undersized, pressure will drop, coverage may become uneven, and application rates may fall below label requirements.

Higher Application Rates = Higher Flow Demand

What if you need to apply a higher application rate in the future (GPA)? This will either require more pressure or a slower travel speed. However, this limits the sprayer. You can only increase pressure or decrease speed so much before needing to swap out your nozzles for larger ones.

Larger nozzles will directly increase how much fluid the pump must deliver. If you change nozzles to increase your rate, you won’t want to need to change out your pump as well. Account for this upfront, and you can be confident your sprayer will handle any future jobs.

Account for System Losses and Bypass

Don’t forget that sprayer systems often use bypass regulators or agitation systems that recirculate fluid back to the tank. This “extra” flow also comes from the pump and needs to be accounted for.

A good rule of thumb: add 20–30% over your calculated nozzle GPM to accommodate system losses and agitation. Do note, if you use the same sprayer for two or three applications that require very different flow rates, figure 20-30% above the job that demands the highest flow rate.

Now, this is a rule of thumb. The best route is to research the nozzles, the agitation jets, rinse nozzles, bypass valves, etc. Understanding the flow requirements for the boom as well as all the other accessories on the sprayer, will help to ensure you pick a large enough pump without unnecessarily oversizing it.

Pump Type: Determine Pressure Required

The other half of sprayer pump performance to consider is pressure. The flow requirement tells us the output we need from the pump; however, the pressure required will tell you the type of pump you need.

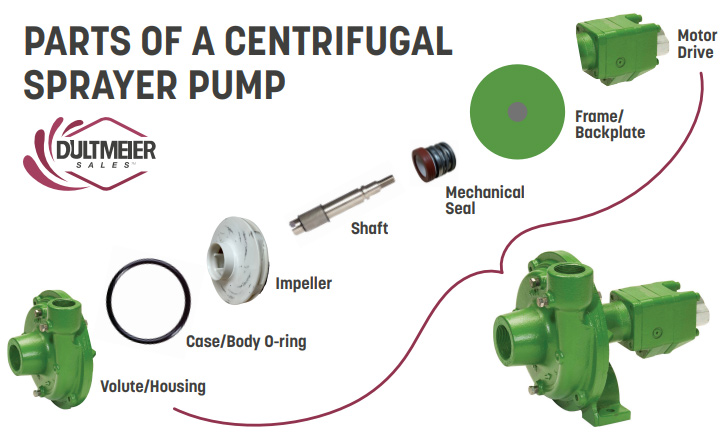

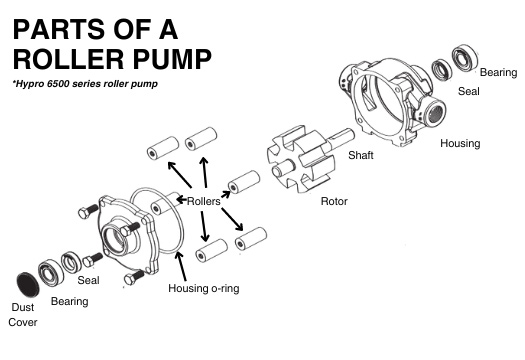

Boom sprayers and spot sprayers are going to be considered low-pressure applications. This would be about 15-120 PSI. Centrifugal pumps, roller pumps, and 12V diaphragm pumps will meet this requirement.

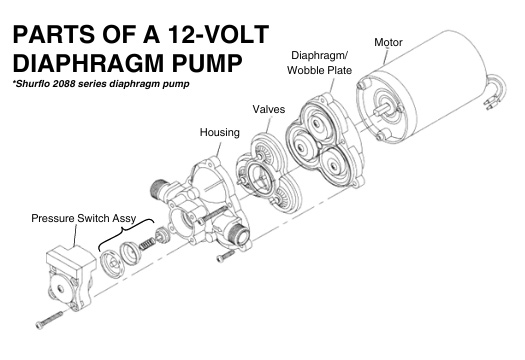

Centrifugal pumps offer the highest volume. They are very common on larger agricultural boom sprayers as well as de-ice sprayers. 12V diaphragm pumps are used solely for low-volume applications such as small boom sprayers and spot sprayers.

Sprayers where you need to reach a great distance with a spray gun will require more pressure. This is especially important for reaching tall trees. Engine-driven diaphragm pumps offer not only the flow but also the high pressure required to spray fluid 40-50 feet or even more. Typically reaching a pressure of 500 PSI or more.

Our sprayer pump guide will break down each of these pump types in greater detail and offer you specific examples of each pump type for various applications.

Specific Sprayer Pump Sizing Examples

Let’s look at a few real-world examples to show how pump sizing works in practice:

Pull-Type Boom Sprayer Pump Sizing

Scenario:

- Fifty-foot wide boom with 30 nozzles

- Plan to spray 10 GPA rate at about 6 MPH

- Nozzle size required: Yellow nozzle = 0.2 GPM @ 40 PSI.

Step 1: Calculate total nozzle output

30 nozzles × 0.2 GPM = 6 GPM

Step 2: Add margin for system demands

6 GPM × 1.3 (buffer for agitation, speed fluctuation, etc.) = ~7.8 GPM

Step 3: Consider an increase in rate or speed

15 GPA rate at the same speed would require 0.3 gallons per minute per nozzle. This can be achieved with the same nozzles at higher pressure or with a larger nozzle (Blue nozzle = 0.3 GPM at 40 PSI).

- 30 nozzles x 0.3 GPM = 9 GPM. 9GPM x 1.3 buffer = 11.7 GPM.

✅ Pump Recommendation: A Pump capable of 12 GPM at normal operating speed would work for these scenarios. Most agricultural sprayers use centrifugal pumps, and these are easily going to produce this amount, often much more. This would make the sprayer very versatile for higher volumes, such as applying fertilizer.

Examples: Ace FMC-HYD-204

Tree Spray Rig Pump Sizing

Scenario:

- High-pressure tree spraying with a hand gun

- Spraying trees 40-45 ft tall

- Required GPM: 10

- Required PSI: 500

Step 1: Calculate total output

1 × 10 GPM = 10 GPM

Step 2: Add buffer for pressure loss and surge

10 GPM × 1.3 = ~13 GPM

✅ Recommended Pump: 12–15 GPM diaphragm pump capable of 500+ PSI.

Examples: Udor Kappa 55, - AR503, - AR50

Spot Sprayer Pump Sizing

Scenario:

- Small ATV sprayer

- Handgun use only

- Nozzle uses 0.5 GPM at 40 PSI

Step 1: Total output = 0.5 GPM

Step 2: Add a small buffer for pressure regulation

0.5 x 1.3 = ~.65 GPM

✅ Recommended Pump Size: 1.8 GPM 12-volt diaphragm pump. There are 12V pumps that are lower in flow and cost; however, they are limited in pressure and may not provide the spray distance you need. So in this case, we over-size the pump slightly to ensure it performs.

Example: Shurflo 8000-543-236

Conclusion

Getting the right size pump for your sprayer isn’t just about performance—it helps your equipment last longer and work more efficiently. When you take the time to calculate your flow rate, consider your pressure needs, and match it all to the right pump type, you’ll set yourself up for reliable, consistent spraying. A little planning up front goes a long way in making sure your sprayer does its job without headaches.

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.