Ever wondered why some anhydrous nurse tanks empty faster than others, or why your flow rates seem to fluctuate without warning? The secret lies in understanding the nuances of liquid withdrawal tank valves and the plumbing from nurse trailer to the tool bar affects the flow of anhydrous ammonia. In this post, we'll uncover the factors that alter these flow rates and reveal tips that can help you boost your efficiency.

Understanding Characteristics of Anhydrous Ammonia

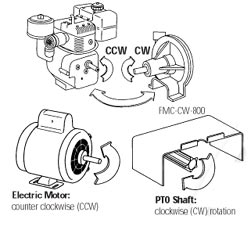

Anhydrous Ammonia or more commonly known as Nh3 is a common fertilizer that provides a wonderful supply of Nitrogen to crops. First and foremost, let's get some basics down on this fertilizer. In its natural state, Nh3 is a gas. When pressurized, the anhydrous ammonia converts to liquid form. By pressurizing a vessel such as a nurse tank we can transport the nitrogen rich fertilizer from a bulk storage facility to the field. Because anhydrous ammonia is a gas, in its natural state, it wants to return to that state. Therefore, any pressure drop in a plumbing system allows the liquid to vaporize.

Once Nh3 vaporizes the plumbing system becomes exponentially less efficient and, therefore, you as an applicator become less efficient. Bottom line - if you have a poor or inefficient plumbing system you will spend more time in the field. Because you have to run your tractor at slower speeds in order to apply the same amount of Nh3. The longer we are able to keep the anhydrous ammonia in liquid form, the less product we lose to the atmosphere as it exits a knife orifice.

Testing Nurse Tank Valves

Now that we have covered a little background information on Nh3 let's discuss liquid withdrawal nurse tank valves. Nurse tank valves may be rated the same, but they are NOT built the same. Take it from Judd Stretcher with Continental Nh3 Products. Judd insists on nothing but top notch quality for the products that Continental turns out. If you could achieve 20% greater tractor speeds by simply changing out your nurse tank valves, would you? Let's look at a scenario from a recent field test that Continental Nh3 Products performed.

Continental lined up their B-1206E, B1206-F, A1406-F, A1406-FBV and A1507-F against some of the top names in industry. What Continental found was staggering. Through standard plumbing equipment, 1-1/4" hose, break away and 1-3/4" acme fittings and a single Continental 30GPM Heat Exchanger Judd was able to prove that quality and efficiency really do pay off.

NH3 Withdrawl Valve Flow Ratings Explained

Before we continue, let's clarify the ratings on valves. If a liquid withdrawal valve is rated to 42 gallons per minute (GPM), like the B-1206-E or F you MUST understand that this is not the product flow rate of the valve. A valve "rating" in the Nh3 world actually identifies the flow rate at which the excess flow check will engage. This is another safety feature mandated in the anhydrous ammonia world. A valve rated to 42 GPM will close and not allow product to flow from the nurse vessel if the flow rate EXCEEDS 42 GPM.

This is designed to protect the operator if there is a catastrophic release - such as a hose failure. The nurse vessel will remain sealed due to the excess flow check. By having this excess flow check in place we don't allow the tank to completely evacuate - thus protecting the operator. So, a valve that is rated to 42 GPM, by industry standards, will actually flow around 24 GPM of product through standard plumbing equipment listed above. In regards to this specific field test, we are concerned with product flow rates.

Continental was able to find that their valves actually outperformed the competition by 10-20 percent. Their valves are able to achieve this due to design and quality. Even a one to two PSI drop at the nurse tank valve can allow for a drastic expansion of product which then allows the Nh3 to vaporize.

The more vapor you put into a heat exchanger the less efficient the heat exchanger, or cooler, is and that ultimately leads to less product going in the ground. Which finally boils down to you spending more time in the field. I will ask the question again, if you can increase your tractor speed by 10-20%, because you have improved the efficiency of your plumbing system, would you?

Money in Your Pocket

Let's look at a basic calculation for Nh3 application: If you are applying 200lbs/acre of Nh3 running 5 mph across a tool bar 55 feet wide you will need a system that can flow 27 GPM as you will be applying 1620 gallons per hour. So if the price of anhydrous ammonia is projected to retail for $350/ton in eastern Nebraska this fall. An application rate of 27 GPM. Means that you are spending $1560/hr (math calculations below). You could theoretically save $312/hr from increasing your plumbing efficiency by 20%. And that, you can take to the bank - calculate that over a 10 hour day and you're looking at savings of roughly $3,118/day. Put that number across an entire season and think what you could do with those savings! If you have further questions check us out at here or give us a shout at 1-800-228-9666.

Math Calculations:

8910lbs/2000lbs = 4.455 tons*$350 = $1559.25/hr - total expenditure on Nh3/hr

(Nh3 weighs 5.5lbs/gal so 1620 gallons = 8910lbs; then 8910lbs * .20 = 1782lbs/hr saved which = $312/hr.

*At the time of writing this Nh3 projections for fall in eastern Nebraska are around $350 retail. Nationwide average is approximately $300/ton.

If you found this post useful feel free to share with friends, family, and colleagues. We are here to help and share our knowledge. If you have further questions don't hesitate to contact us. Thanks for stopping by and take care!